Stories

Parisian Ties

1919-

A chance meeting in the dining car of a train crossing America sparked the beginning of a New Zealand manufacturing business that celebrates its centenary in 2019. Callil Abdallah, who had come to New Zealand from the former Ottoman Empire, was a man blessed with an adventurous spirit and entrepreneurial acumen.

As the post World War One economy began its recovery, Callil (who was in the jewellery trade) travelled to the United States in search of inspiration for a new venture. While on a train he struck up a conversation with a tie maker who explained to him how to make a neck tie. Callil drew the pattern, as described to him, onto a napkin and tucked it into his pocket where it stayed until he returned to New Zealand. Once home, he gave the sketch to his daughter Ruby who was a dressmaker on Queen Street. She made up the tie to the pattern and Callil saw its potential.

At the beginning of the 20th century many items of clothing were being imported from overseas but Callil saw that the neck tie could be manufactured competitively in New Zealand. In 1919 he established a small tie-making business in central Auckland. The aspirational name 'Parisian' was chosen to both reflect the sophistication of fashion in the French capital and also to counter the general distrust of the quality of New Zealand-made products at this time.

With guidance from his financially astute general manager, Joe Weir, Parisian purchased property at 74 Upper Lorne Street where it opened a factory and showroom. By 1921 there were 50 staff employed in the factory, including his daughters Ruby, Iny and Olive.

The business received a warm welcome from menswear retailers who were often buying designs from overseas that were not always well-received by their customers. Parisian’s ties were designed for the New Zealand man who, according to the Auckland Star (19 September 1921), was fastidious in regard to his neckwear. "Loud colours and weird designs which 'go' in some countries are not popular here, most men requiring quiet tones and neat articles," reported the newspaper. "Great care is therefore taken in buying materials … demanded by men of taste."

Callil Abdallah (left) inspecting bolts of fabric. Image © Parisian Neckwear.

Fabric choice was important in setting the Parisian standard and finding something unique and special was a constant challenge. The designs on offer from local fabric merchants were somewhat limited and international travel was by ship and time-consuming. So, in 1926, Callil made a bold move, sending his son Harry to open the Parisian sourcing office in London. Harry travelled throughout the UK and Europe working with specialist weavers and commissioning fabric exclusively for Parisian’s ties. A century later, many of the relationships Harry forged have endured.

During the 1924 Christmas rush at Parisian, Joe Weir asked an acquaintance, 22-year-old Barney Crompton, to help out. Barney never left, staying with the company for 60 years until he passed away at the age of 82. He officially became part of the Parisian family when he married Callil's daughter, Iny Abdallah, in 1933. Barney’s son and grandson have gone on to helm the company.

Parisian staff photo, 1933. Image © Parisian Neckwear.

By the 1930s, the Parisian label was a household name with 'Parisian Neckwear' being sold in retail and department stores throughout New Zealand. The New Zealand Draper, Clothier and Boot retailers' magazine recorded in October 1930 that the Parisian Neckwear Company had earned its success due to "... the quality, finishes and style of the goods". It also noted the relationship with their customers who they dealt with personally, introducing an 'Exclusive Design Service' which meant that a client could confine particular styles and fabrics exclusively for sale in their stores ensuring that each had a unique and personalised offering of ties. Alongside their eponymous label they also offered 'President by Parisian' and 'Rue Royale'.

Newspaper ad for Parisian Ties, Poverty Bay Herald, 1929.

At the outbreak of the Second World War, the staff was nearing the 100 mark.

The post-World War Two era that followed was a boom time for ties as fashionable clothing came back into the limelight. In the 1940s ties were wide and flamboyant with large geometric motifs that were woven or printed on to the fabric. In the 1950s, influenced by European trends, Parisian's ties became narrower and less decorative. It was the birth of the skinny tie.

Barney and Digby Crompton with the Parisian sales team. Image © Parisian Neckwear.

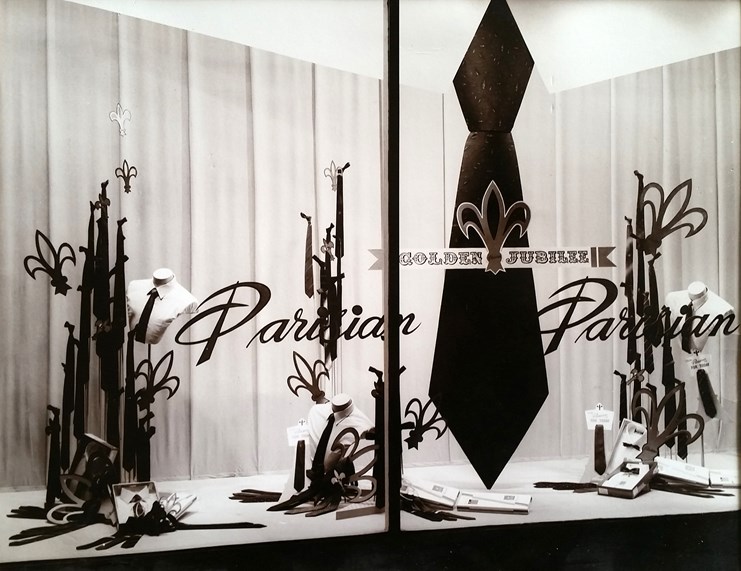

In 1969 Parisian celebrated their Golden Jubilee. Barney Crompton, by then managing director of Parisian, was applauded by the Auckland Star (21 October 1969) for his enthusiasm and ingenuity for tie-making. Barney was particularly interested in what the article described as "labour saving gimmicks". One of his "gimmicks" - made from a golf club - is still in use today in the workroom.

Parisian Ties celebrated its Golden Jubilee in 1969. Image © Parisian Neckwear.

Barney and Iny’s son Digby learnt the trade from his father and took over the management of the business in the 1970s. One of Digby’s early challenges was to find a new site for the factory when plans for Mayoral Drive were confirmed. The Lorne Street premises, which been expanded twice through the decades, was right in the centre of the planned road. In 1984 Parisian moved up Queen Street to their current home in Poynton Terrace on the edge of Myers Park.

Many of Callil's extended family worked for Parisian, including his son-in-law Barney Crompton, grandson Digby Crompton, and in the second photo, daughter Olive Abdallah (left). Image © Parisian Neckwear.

Digby faced two further significant challenges during his leadership. A decade after the Labour Government removed import restrictions, much of New Zealand’s apparel manufacturing industry had closed down. Taking a stand against the mass exodus to off-shore sourcing that most apparel brands were making, Parisian held fast in its commitment to local production.

The second challenge was to the very item for which Parisian was known, the tie. The 'dotcom' influence on workplace dress led a steady global shift away from formality in the office. Concepts like 'casual Friday' soon expanded to blur the lines between clothes for work and those for home. However, when the tie runs in the blood, the passion for the business’s DNA gave Digby a different perspective and he did not give in to the commercial pressures that swayed so many others to quit.

Having weathered many storms, the business of making ties in New Zealand is not without challenge. But that family passion, 100 years in the making, is what is driving growth in Parisian’s tie business today.

Parisian advertisement from the 1960s. Image © Parisian Neckwear.

As the fourth generation of family, being part of Parisian is very important to current managing director, John Crompton. "I remember as a small boy, coming into the factory, choosing a fabric I liked and having a little tie made especially for me." Like those who went before, John spent time working through every aspect of the local production and undertook training in the weaving process with fabric mills in Germany and Italy. This intimate knowledge of process and materials continues to set Parisian apart globally in its ability to create unique collections.

John Crompton in the Parisian workroom, 2019. Image © Parisian Neckwear.

Many of Parisian’s own labels have been sewn to their ties, including Fellini, Ristretto, Bottinelli, Kiwi Country and of course Parisian. Of particular note is the long-standing relationship with the Paris-based couturier, Pierre Cardin. As the first company in New Zealand to partner with the French designer, Parisian has worked with Pierre Cardin to make ties under license for the New Zealand market for over 40 years. More recently, Parisian have worked with Liberty of London to make their classic prints and latest seasonal collections into ties, bow ties and pocket squares.

Relationships are at the core of Parisian’s story. They continue to sell direct to their retailers as well as maintaining their bespoke design-and-make service for many of New Zealand’s schools, clubs, businesses and fashion houses.

They have taken an intentional decision to stay 'New Zealand made'. A move to manufacture overseas was rejected in the early 2000s. "It was difficult," John says, "when the market was telling you that price was more important than where a garment was made." But Parisian took a long view. They realised that if they lost the skilled people, they would never retrieve them. "Although the immediate market indicators suggested our model was not viable, we knew that if we could ride through, there would eventually come a time when locally-made was appreciated.

"That is the position we're sort of on the cusp of entering now," John told Metro magazine in 2017. Since then, John has seen a continued groundswell of young people fascinated by Parisian’s workroom, where raw materials are transformed into finished articles. "In today’s world, the clicking of a button has distanced us from the reality of our purchases. The counter movement to this is a search for ways to close that gap and experience a more real connection by purchasing locally-made. It’s great to now be a part of that movement."

The current fashion for conscious consumption and wearing locally made has again taken Parisian ties into the spotlight. Typified in campaigns such as 'Who made my clothes?', the decision to keep making in New Zealand has meant the business is thriving on genuine passion as it celebrates 100 years of making ties in New Zealand. More than ever in history, we no longer wear ties to fit in, but as statement of individual expression.

Text by Kelly Dix. Banner image © Parisian Ties.

Last published March 2019.