Stories

Making Ties in New Zealand

1919-

Until Callil Harry Abdallah established Parisian Neckwear in 1919, almost all the ties worn in New Zealand were imported. The market for ties was rather precarious for retailers who were buying sight unseen from overseas and often found themselves faced with unsold stock from distant manufacturers.

Auckland department store Smith & Caughey’s would have been one of the first of the early tie importers. Following a visit to the store’s menswear department in 1900, a reporter for The New Zealand Graphic wrote: "Ties, scarves and all the smaller paraphernalia of masculine adornment are stacked and stowed in inconceivable variety."

At the beginning of the 20th century much of the clothing worn in New Zealand was manufactured overseas and imported by agents. As the population grew, many of these items began to be made locally. The First World War contributed to the domestic manufacturing sector with its demand for uniforms and other war-time items. With military contracts to fulfil, many shoe and garment makers expanded their businesses.

In the years that followed the war, a number of businesses established their own factories. Callil Abdallah's Auckland business was one of many garment and fashion accessory manufacturers established in the post-war period and the first recorded to be making ties in New Zealand. Another early tie manufacturer, Sander Tie Company, was established in Wellington in 1921. As the modern tie established its place in 20th century dress, several other tie making operations such as Klipper, John Webster and later Eskay, were established.

The Parisian Neckwear factory on Lorne Street, Auckland. The New Zealand Draper, Clothier and Boot Retailer, 1 October 1930.

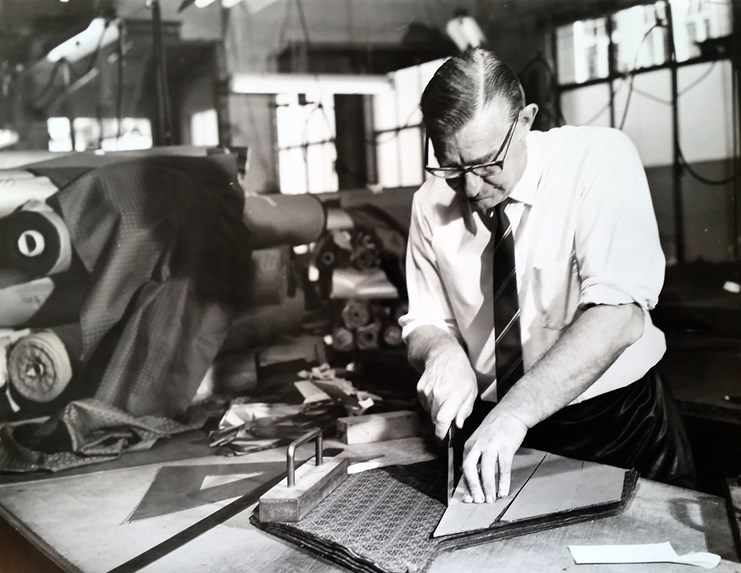

An Auckland Star article (16 September 1921) about Parisian Neckwear described the complexities of tie-making. Different pieces of machinery, some custom built in-house, are used to execute the many steps which begins with cutting the fabric. "There is an art in cutting a tie which few men realised," the article states. While the process was modified after 1926 with the introduction of the bias cut tie, the production of ties has changed very little since. It is a remarkably complex process for such a small piece of clothing. With about 14 individual steps it relies on trained and skilled staff. The bias cut tie makes use of the relative qualities of the warp and weft of a fabric. The warp is strong and rigid while the weft tends to be soft and pliable, together they allow a tie to be sturdy enough to be pulled into a knot and soft enough to flow down the front of a shirt and flexible enough to recover its shape when it is released from the knot. The skills of the cutter remain key to getting a quality result.

Harry Gedye of Parisian cutting the three parts of a tie. Image © Parisian Ties.

Retailers were quick to support the local industries whose products were accessible and made by people who understood the local situation. Their customers, however, weren't always so positive about New Zealand-made goods which they often saw as being of inferior quality to the imported product. In an effort to counter this prejudice, Callil called his business Parisian and for the first five years of business, no mention was made of where Parisian ties were made. By 1926, things had started to change and Parisian became part of an early 'Buy New Zealand-made' campaign that emerged mid-decade.

Parisian was part of an early Buy New Zealand made campaign that started in the mid-1920s. Ads from the New Zealand Herald 16 November 1926 and Evening Post 30 May 1932.

This campaign ramped up during the Great Depression as the economic downturn devastated New Zealand businesses. Facing high unemployment rates and a flood of imports, the government introduced licensing. From 1938 the government used import licences to restrict the number of goods brought into New Zealand to encourage and support local manufacturing and employment. It also increased the customs duties charged to importers. These tariffs were a percentage of a garment’s price and were paid to the government. Protected by these tariffs, the New Zealand clothing industry boomed. In the 1950s it employed about 80,000 people. Different sectors formed their own associations to advocate for their specific interests. For many years there was a tie manufacturers’ association which lobbied together and advertised to the trade as a group.

Photos of Parisian Ties and the workroom by Whites Aviation, 1947. Images courtesy of Alexander Turnbull Library WA-07740-F, WA-07743-F, WA-07744-F, WA-07742-F.

Although intended as a temporary measure, the direct control of imports became a distinctive feature of New Zealand economic policy until the mid-1980s when a series of economic changes began to seriously affect the fortunes of the industry. The Fourth Labour Government, elected in 1984, introduced neo-liberal social and monetary policies that saw the removal of a swathe of regulations, subsidies and tariffs including those related to clothing manufacturing. The resulting flood of imported garments provided stiff competition and many manufacturers struggled, often moving their operations offshore to remain competitive. The 1987 stockmarket crash delivered a second hit to the industry as New Zealand entered an economic recession.

As a consequence of the reduction in local manufacturing many craft skills have been lost as the jobs have disappeared. In the last three decades, the industry has downsized by about 90 percent.

One of the few survivors, Parisian Neckwear Company, continues to preserve its knowledge about making ties. A family owned business with loyal staff, many of whom have been with the firm for decades, it continues to employ the same methods that have stood the company in good stead for 100 years.

Now helmed by John Crompton, Parisian have taken the long view, continuing to manufacture their ties exclusively in New Zealand and maintaining the high standards of 'quality, finishes and style' on which they built their reputation. With their unique expertise and local production capability they also make bespoke ties for everyone from schools to corporates to fashion brands.

Benny Castles, menswear designer at fashion label World, finds the close relationship to Parisian invaluable. "From a new collection item to a 'one off' tailor-made piece we have been so lucky and honoured to have grown a relationship with John and the Parisian team, who are just up the road! This has meant a sharing of aesthetics and skills which allow us to continually provide our customer with an extended universe of beautifully hand crafted objects - made here under our watchful eye in New Zealand."

The loyalty and respect that the company engenders is epitomised by Auckland menswear retailer, RJB Design who have sold Parisian ties and belts for 20 years and describe themselves as "huge" advocates of New Zealand made. "We love sharing the genuine story of real craft that underpins the Parisian name and everything they make," says owner Ronald J Biddick.

With backing from key fashion arbiters, the future of local production and Parisian Ties seems assured for some time to come.

Watch a video of the whole production process at Parisian Ties.

Text by Kelly Dix. Banner image © Parisian Neckwear.

Last published March 2019.